Explore Cutting-Edge Injection Molding Applications in the Automotive Industry

In the rapidly evolving automotive industry, precision and efficiency are paramount. Our injection molding solutions offer unmatched precision and cost-effectiveness, enabling car manufacturers to achieve superior component quality and durability. From intricate dashboard components to robust exterior car parts, our technologies help drive the future of automotive manufacturing

- ISO9001:2005 Certificated

- Tight Tolerance ±0.01mm~ ±0.005mm based on designs and materials.

- 7x24h Engineer Supports

- Home

- Industries

- Automotive

Automotive Mold Solutions

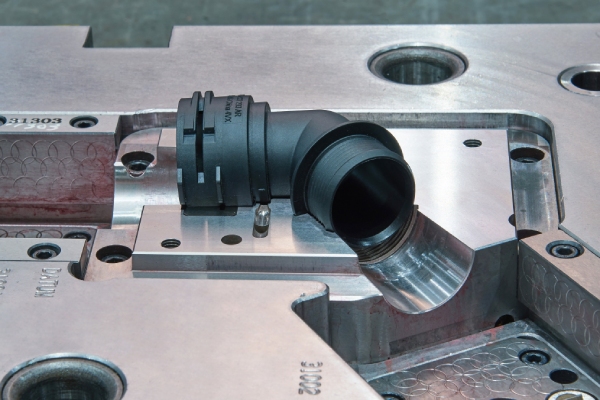

Our extensive range of injection molded parts specializes in components that enhance vehicles’ functionality and aesthetics. Utilizing advanced injection molding techniques, we ensure each product meets the highest standards of quality and performance:

- Automotive Lighting: We produce sophisticated enclosures for automotive lighting systems, including headlamps and tail lights, ensuring high clarity and durability.

- Bumpers: Our robust bumpers are designed for maximum impact resistance and are tailored to meet the specific design requirements of different vehicles.

- Decorative Strips: Customized decorative strips that enhance vehicle aesthetics without compromising on longevity or material integrity.

- LED Lenses: Precision-molded LED lenses that optimize light distribution, providing superior illumination and efficiency.

Why Choose Sino-Mold?

Get Instant Quote

Email us and Upload Your Design; our Expertise Experts Will Conduct a Manufacturing Feasibility Analysis of Your Parts and Provide Suggestions to Improve Efficiency and Save you Time and Cost.

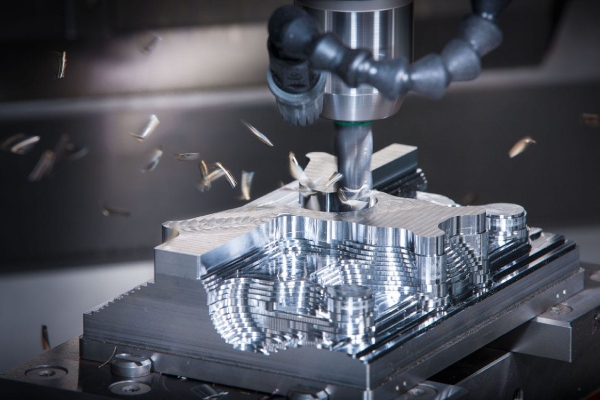

Strong Capabilities

STCNC Machining and Our Partner offer almost every part you can think of, from Simple cylindrical geometrical parts to Complex Shape Automotive Parts. You can always get what you want.

Fast Delivery

Lead time From 7 days. STCNC can strictly Control the lead time by Combining our high-speed and precision CNC turning and milling centers with our Experienced Experts.

Qualtiy Assurance

As an ISO-certified company, we apply this standard to our production line for quality control. STCNC Can also Provide First Article Inspection Reports, Full-Size Inspection Reports, and Material Certificates to ensure you can get Qualified Components.

Automotive Mold Manufacturing Capabilities

Relying on SINO-Mold’s powerful production capabilities, we streamline the process of taking automotive parts from prototyping to mass production. This will help you get your parts into production quickly.

Frequently Asked Questions

Yes, we do. We have over 15 years of experience exporting molds, with more than 70% of our molds shipped internationally.

We can manufacture between 50 to 60 sets monthly, depending on the size and complexity of the molds.

We have approximately 100 employees.

We can handle molds up to a maximum weight of 15 tons.

About 30% of our molds are for the automotive sector. We have produced molds for major brands like Tesla, Volkswagen, Honda, Ford, Toyota, and Lamborghini.

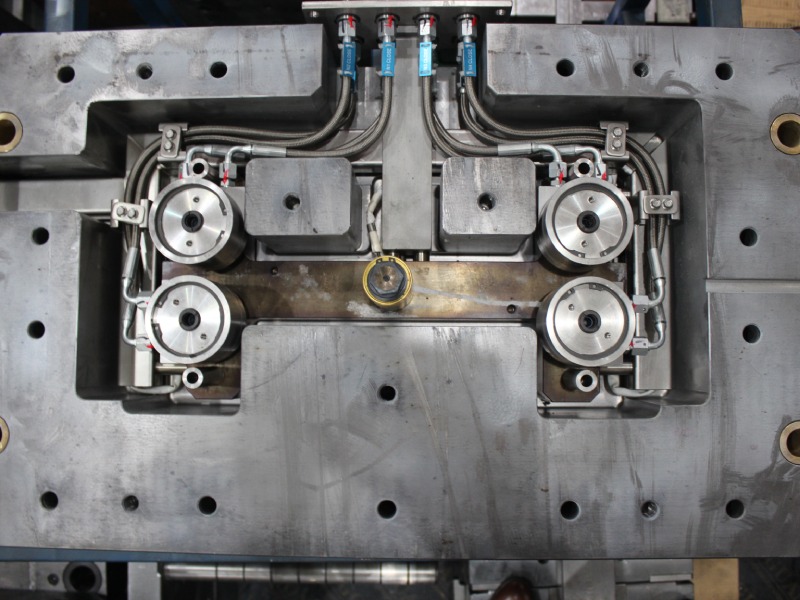

Yes, we specialize in precision molds with mold tolerances of +/-0.05 to 0.01mm and product tolerances of +/-0.02mm.

Yes, we specialize in precision molds with mold tolerances of +/-0.05 to 0.01mm and product tolerances of +/-0.02mm.

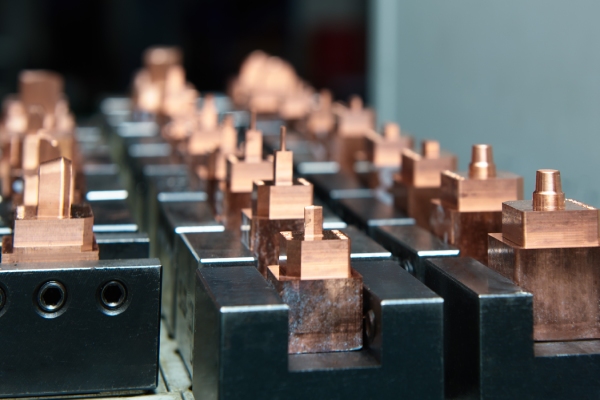

We only use high-quality raw materials such as P20, P20H, 718H, NAK80, 1.2311, 1.2378, 1.2344, 1.2343 ESR, 1.2767, H13, 8407, 420SS, S136, S-7, etc., sourced from renowned suppliers like LKM and ASSAB. If specified, we provide a steel certificate and a heat-treatment certificate with the molds upon delivery.

The choice of hot-runner systems is determined by our customers. We partner with well-known suppliers such as INCOE, YUDO, DME, Mold-Masters, HASCO, Synventive, and Husky.

We prefer 2D and 3D part files along with mold specifications for quotations. We primarily utilize software like UG, AutoCAD, SolidWorks, and Pro-E. For 2D, we accept JPEG, PDF, DWG, and DXF formats. For 3D, we accept PRT, SAT, IGES, STEP, X_T, SLDASM, SLDPRT, and CATPart formats.

The standard lead time is about 4 weeks, although this can vary from 3 to 8 weeks depending on the mold’s size and complexity.