We frequently hear about family mold, but what exactly is it? When will we think about designing it? Louise relays the following information from the Sino-Mold Industrial company. Your helpful suggestions are always appreciated. #plasticinjection #injection molding #CNCmachining.

A family mold is a type of mold that includes multiple part numbers within the same mold, with the option of multiple cavities for each part number. It may be less expensive than molds designed solely for one part number. This approach is appropriate for all of our molding processes, including injection molding, insert molding, micro molding, compression molding, and transfer injection molding.

What does the family mold look like?

As an example, here is a mold design of a family mold with 5 different parts on ONE mold.

Family injection Molds Benefits

Cost-effective

By creating one type of tool that can be used to produce numerous parts, with the same color, same material, but different profiles and different shapes in the injection molding process. companies can save money on the cost of designing and manufacturing tools.

Family injection molds can be used to produce large quantities of identical parts in one go in this way, manufacturers don’t need to spend money on creating new molds for each product, which would be more expensive than creating just one or two molds. so family mold is the most popular plastic injection mold.

Time-saving

It can reduce the lead time needed to create a part from scratch. what’s more, if a manufacturer needs to produce a set of plastic parts and needs to together in an assembly, then, using a family mold can produce all the parts in one production cycle time, rather than having to produce each part separately, which can be time-consuming.

Ideal for prototype molds

If the goal of the prototype mold is to produce multiple parts with similar geometries or functions, a family mold can be an efficient option as it allows for the production of multiple parts at the same time, reducing the total production time and costs.

Precise in dimensions

It can be used for mass production needs without sacrificing accuracy or quality control standards for each individual part produced.

Family Molds shortcomings

Family molds have some limitations that can affect their suitability for certain manufacturing applications. Some of the potential shortcomings of family molds include

Flexibility limitation

The design of family molds is intended for the production of more than one cavity part that possesses comparable sizes and shapes, which ultimately constrains their versatility in creating bespoke or unique parts.

This shortcoming can pose significant challenges for manufacturers that require enhanced design flexibility or need to manufacture a diverse range of parts with varying specifications.

Setup Time Increased

Family molds may require more time to set up and change over between different parts with the same material, as the mold must be adjusted to accommodate different part geometries. This can increase production costs and reduce overall efficiency.

Maintenance Issues

Family molds may require more maintenance than dedicated molds, as they are used to produce more than one part with different geometries. This can increase the risk of part defects, as well as the likelihood of defects or other issues arising during production.

Higher Risk of Contamination

Family molds may also be more susceptible to contamination or errors.

Besides family mold, are there any other types of mold?

There are several types of plastic injection molding models based on the number of cavities, The following is a brief introduction to other types. In the later stage, we will update them one by one on the Sino-mold industry LinkedIn platform. Thank you for your support to Louise.

Single cavity molds

It is the most basic type of injection mold. It has one cavity that can be used to produce one part at a time. This type of single mold is more often used by small businesses and hobbyists because it’s easy to set up and operate

Multi-cavity mold

Multi-cavity mold is a more than one cavity injection mold. Because multi-cavity injection molds have multiple cavities that can be used to produce many same parts in a single cycle. This type of mold is commonly used by large businesses because it allows them to make thousands of products quickly and efficiently.

Two-shot or dual-shot molds

Two-shot or dual-shot molds are a type of injection molding tool used to create plastic parts that consist of two or more colors or materials.

Stack molds

Stack molds, also known as stack molds or stackable molds, are a type of plastic injection mold that allows for the production of multiple parts in a single molding cycle. Stack molds have multiple parting lines, allowing for the molding of two or more parts simultaneously, with each parting line forming a separate cavity.

Unscrewing molds

Unscrewing molds are specialized molds used in plastic injection molding that have threads or screw-like features incorporated into their design. These threads are used to create parts with internal threads or screw-like shapes, such as caps, lids, and other threaded components.

The difference between family mold to others ?

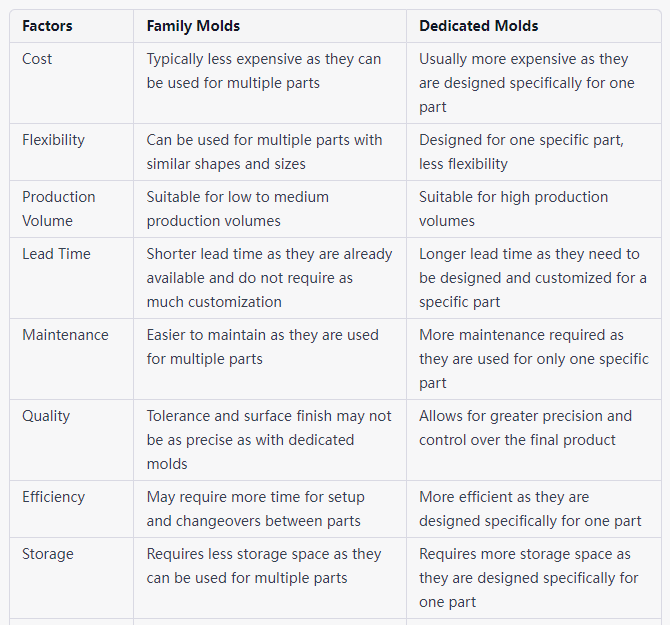

[Application compare]

Factors Affecting Family Molds & Dedicated molds

Anyway, since they are many type of molds, you may still need a professional tooling factory help you to make them.

How to choice to make family molds or multi-cavity molds? If you are interested, come to contact us with your project, you will find the best solution.