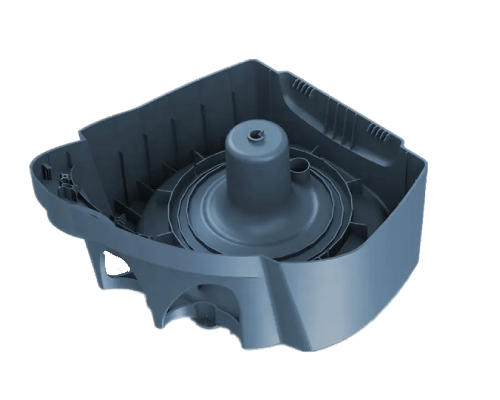

PPSU CNC Machining

STCNC Machining produces high-quality PPSU parts with excellent mechanical properties and accuracy. We offer tight tolerances and utilize 3-axis, 4-axis, and 5-axis CNC milling processes.

CNC Machining in PPSU Materials

PPSU, which stands for polyphenylsulfone, is a chemically known amorphous plastic material. It exhibits a high glass transition temperature and demonstrates low moisture absorption characteristics.

Get Your PPSU Machined Parts in the Soonest Lead time from 5 Days!

Available Materials

PPSU

PPSU is an amorphous material with a high glass transition temperature and low moisture absorption. It can keep rigidity over a wide range of temperatures.it is also Featured with good impact strength and chemical resistance.