Cooling design and methods in Plastic injection mold design

In the intricate world of plastic injection molding, success hinges on a seemingly understated yet profoundly impactful stage—cooling. As a Chinese manufacturer specializing in molds and plastic injection molding, we must delve into the depths of cooling design and methods to share valuable insights with our customers.

Importance of Cooling Design

The cooling design is not just about keeping things cold but optimizing cooling lines throughout the entire production process. Proper cooling ensures uniform solidification and minimizes distortion, warping, or internal stress within the various injection molded side parts.

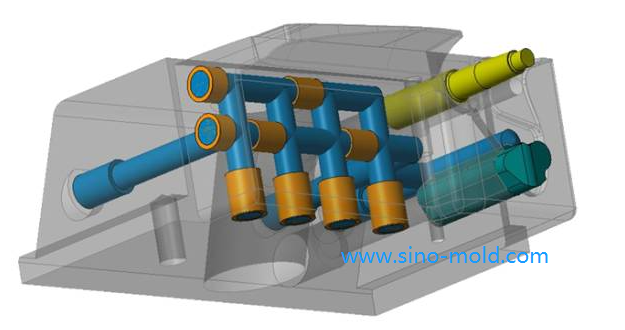

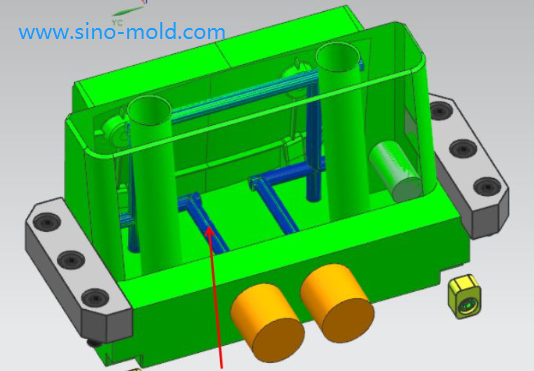

What are the Cooling Lines?

The cooling lines support uniform cooling of injection molds and provide conductive parts without cracking or warping to produce. The injection molding process is heated by injecting resin into mold cavities using heat sinks. The plastic fills a cavity, conforms, and cools the cavity. This cooling system returns a finished component to a solid state but an inconsistent temperature on molds may result in uneven cooling resulting in component defects. Injection mold cooling correctly can reduce defects, repair, reworking, and materials waste.

The Intricacies of Cooling Channel Placement

Precise placement of cooling channels is crucial. It’s a delicate balancing act. Design engineers meticulously analyze the geometry of the part to determine the optimal location for cooling channels.

Straight Line Cooling vs. Conformal Cooling

Two different types of cooling tubes are employed on a mold: straight line and conformal. Straightline cooling is the standard cooling technique in injection mold cooling systems. The cooler line or the channel is cut on a straight line into metal molds to create heat. Side channels or branches intersect with the main channels allowing more surface area for cooling. After forming and molding plastic parts, the cooler fluid flows into the channel. Using these cooling mechanisms, the mold core can be heated out of the injection mold. Generally, straight-line coolants are used to manufacture smaller components. Conformally cool injection molds are commonly used for complex components.

Balancing Act: Cooling Time vs. Cycle Time

The cooling time directly impacts cycle time—the shorter the cooling passage, the better. Engineers work on finding the perfect balance between cooling time and cycle time, optimizing productivity while maintaining quality.

Cooling-Related Defects

Residual stresses: Shear stress created when pushing the plastic into the mold creates residual stress in the finished product. The melt temperature and gate location can affect residual stresses by resulting in inconsistent properties including nonuniform temperatures and flow. The use of residual stress may be beneficial for the reduction of time especially in high volumes of manufacturing. Part shrinkage occurs if the part of the mold has not been adequately cooled before it is removed. Sometimes expansion in different directions causes pressure cracks on parts.

How to balance cooling time and cycle time?

Process Analysis: Begin by thoroughly analyzing your manufacturing process. Understand the materials, machinery, and equipment involved. Identify critical parameters such as the ideal cooling time required for each specific material and product.

Design Optimization: Review the design of molds, casting patterns, or any equipment involved in the cooling process. Consider modifications that can enhance heat dissipation. Utilize advanced design software and simulation tools to model and test different designs.

Cooling Techniques: Explore various alternative cooling techniques, including conformal and cooling channel design, which involves designing cooling channels that closely follow the contours of the product. Experiment with different cooling mediums like water, air, or specialized cooling gels.

Simulation: Use simulation software to predict and analyze the impact of different cooling strategies on cycle time and product quality. This allows you to make informed decisions and fine-tune your approach.

Monitoring and Control: Implement real-time monitoring and control systems to track the cooling process. This helps in identifying deviations from main cooling line and making immediate adjustments to maintain the desired balance.

Quality Assurance: Continuously monitor the quality of the finished products. If you notice any issues related to rapid cooling, such as material stresses or deformities, consider adjusting your cooling parameters to strike a better balance.

Iterative Approach: Recognize that achieving the perfect balance is an ongoing process. Continuously gather data, analyze results, and refine your cooling strategies over time.

Employee Training: Ensure that your team is well-trained and knowledgeable about the importance of balancing cooling time and cycle time. Encourage them to actively participate in the optimization process.

Collaboration: Collaborate with suppliers, consultants, and industry experts who can provide valuable insights and best practices for your specific manufacturing process.

Benchmarking: Benchmark your cycle time and product quality against industry standards and competitors. This can help you set realistic goals and identify areas for improvement.

Documentation: Maintain detailed records of your cooling time optimization efforts. Document successes, failures, and lessons learned to build institutional knowledge.

Continuous Improvement: Embrace a culture of continuous improvement within your organization. Regularly review your processes and seek opportunities to further enhance cooling time efficiency while upholding product quality.

Balancing cooling time versus cycle time is a dynamic, fluid and evolving process. By following these steps and remaining committed to optimization, you can achieve improved production efficiency and increase your product quality, ultimately enhancing your competitiveness in the market.

Hot Spots and Their Implications

Hot spots are areas within and outside the surface area the mold where cooling is less effective. Identifying and mitigating these hot spots is a critical aspect of the cooling system design.

How to solve hot spots in mold design and their associated issues?

Simulation and Analysis: Utilize computer-aided design (CAD) software and mold flow analysis tools to simulate the molding process. These simulations can help identify potential hot spots and their causes.

Optimized Cooling: Design the mold with efficient cooling channels to evenly distribute heat and reduce hot spots. Consider conformal cooling channels that follow the line of the shape of the mold for uniform cooling and improved melt temperature and control.

Material Selection: Choose mold materials that can withstand high temperatures and thermal stresses. Specialized coatings or treatments can also be applied to the surface to mitigate hot spots.

Gate Placement: Optimize gate placement to control the flow of molten material and minimize the impact of hot spots. Proper gate design can help the melt and distribute material more evenly.

Venting: Ensure proper venting in the mold to allow gases to escape during the injection and filling process. Inadequate venting can lead to air traps and hot spots.

Injection Parameters: Adjust the injection system parameters, such as temperature and pressure, to minimize the risk of hot spots. Fine-tuning these parameters can help achieve a more balanced temperature distribution.

Reduced Cycle Time: Minimize cycle time by optimizing cooling processes. Implement quick cooling techniques like high-pressure air cooling system or using air cooling in inserts.

Thermal Insulation: Use thermal insulating materials in areas prone to hot spots. This technique can help reduce heat transfer and maintain uniform temperatures.

Regular Maintenance: Implement a maintenance schedule to monitor and address wear and tear in mold components caused by hot spots. Timely maintenance can prolong the life of the mold.

Quality Control: Implement strict quality control measures to detect and address defects caused by hot spots during production. This may include visual inspection, testing, and statistical process control.

Continuous Improvement: Encourage a culture of continuous improvement. Regularly review and analyze production data to identify recurring hot spot issues and implement preventive measures.

Collaboration: Engage in collaborative efforts with mold designers, engineers, and operators to share insights and collectively work on hot spot solutions.

Solving hot spots in mold design requires a holistic approach, combining design modifications, material choices, process optimization, and ongoing monitoring. It’s crucial to address the root causes of hot spots systematically to achieve consistent molded part quality and production efficiency.

Cooling Methods: The Symphony of Precision

Once the design is in place, it’s time to orchestrate the liquid cooling process.

Water Cooling vs. Air Cooling

Injection moldings can be either water or air-cooled. This must be noted since cooled water has a mixed substance and is intended to provide heat. The cooling towers of the injection molds are mixed using biocides and microbial products to reduce the chances of infection and to control bacteria. In cooling lines near injectable molds, water is mixed with ethylene glycol to prevent corrosion.

Water Cooling: Efficiency Personified

“Water cooling system is the workhorse of the injection molding world. Efficient and versatile, it ensures rapid heat removal from the injection and molding cycle and cooling itself.

How water cooling in mold design can be employed effectively?

Cooling Channels: Design the mold with strategically placed cooling channels. These channels circulate coolant, usually, water cooled down, through the mold to dissipate heat and maintain consistent temperatures. The placement and geometry of these channels should target areas prone to hot spots.

Conformal Cooling: Consider utilizing conformal mold cooling piping, which typically involves designing cooling channels that conform to the shape of the mold cavity or core. This approach optimizes cooling efficiency by closely following the contours and lines of the part.

Cooling Channel Diameter and Placement: The part thickness, diameter, and placement of cooling channels should be carefully calculated to ensure uniform temperature distribution. Thicker sections of plastic in the mold may require larger-diameter channels.

Coolant Flow Rate and Temperature: Control the flow rate and temperature of the coolant to achieve the desired cooling rate. Faster coolant flow and lower temperatures are often used to address hot spots effectively.

Baffle Systems: Baffles or inserts can be added to the cooling channels to enhance heat transfer and redirect coolant flow to specific areas of the resin-filled mold where hot spots or bubbles are prevalent.

Multiple Cooling Zones: Divide the main channel of the mold into multiple cooling zones, each with its dedicated cooling tube and circuit. This allows for precise control over the temperature in different regions on one side of the mold.

Thermal Insulation: To prevent heat loss and ensure efficient cooling, consider adding thermal insulation to areas that require it. This can help maintain the air cooled at desired temperature levels.

Monitoring and Control: Implement a monitoring and control system to regulate the temperature of the coolant and ensure it remains within the desired range. Automatic temperature control systems can help maintain the coolant flows and consistent conditions.

Coolant Quality: Ensure the coolant used is of high quality and free from contaminants that can clog cooling channels. Regular maintenance, cleaning, and coolant replacement are essential.

Simulation: Use mold temperature flow analysis and simulation tools to predict the temperature distribution in the mold and identify potential hot spots before manufacturing the actual mold.

Material Selection: Choose mold materials that conduct heat efficiently, allowing for more cooling phase and better heat transfer between the plastic part of the mold and the coolant.

Water cooling in injection mold part design is a versatile and effective method for managing temperature variations, reducing cycle times, and producing high-quality parts. It is an integral part of modern injection molding processes and contributes significantly to the overall efficiency and performance of injection molds used.

Air Cooling System for Injection Molding

The evaporator can also remove heat from the injecting machine by cooling the system. The vaporization heat is removed using a condensing device. Air cooling systems include a ventilator to circulate cooler air toward molds and a fan exhaust to redirect cold air from the mold. An air injection mold cooling system transfers heat from an injection mold running water lines into the air around these lines in a cooler. Since air transmits less heat than water it is usually needed for cooling to the same extent.

Hot Runners and Cold Runners: A Vital Choice

The choice between hot runners and cold runners significantly affects cooling. Hot runners keep some channels continuously heated, while cold runners save energy by cooling after each cycle.

In the coming article, we will share” How to choose hot runners and cold runners for your mold?”. Welcome to our website: www.sino-mold.com

Beyond Conventional: Innovative Cooling Techniques

Innovations in cooling are continuously evolving. From conformal cooling to gas-assisted cooling, novel methods aim to elevate efficiency and product quality.

In Conclusion: Crafting Excellence, One Mold at a Time

Cooling is the true art of the injection molding process, where precision meets innovation.

As a Chinese mold and injection molding manufacturer with more than 20years+ experience, we understand that every detail in cooling design and methods is critical. Our commitment to excellence drives us to continuously explore innovative solutions and optimize our cooling systems to deliver the highest quality products. In injection molding, cooling design, and cooling methods are inseparable. If you’re interested in how our expertise in injection mold cooling systems can elevate your projects, please feel free to reach out. We’re here to transform your ideas into reality. Sino Mold Industrial.

#InjectionMolding #CoolingDesign #CoolingMethods #ManufacturingExcellence #EngineeringInnovation