In mold design, angled lifters (also known as turn sliders or cam actions) are essential for solving complex part ejection challenges, especially when dealing with undercuts or side features on a part. At Sino-Mold Industrial Co., Ltd., we specialize in precision mold manufacturing and machining, and we’re here to share some insights on when and how to use angled lifters effectively.

When Are Angled Lifters Needed?

1.Parts with Undercuts:

When a part has side features, such as recesses or protrusions, that prevent simple ejection, angled lifters can move laterally or at an angle to release the part smoothly.

2.Aesthetic Requirements:

If the part’s appearance is critical, angled lifters can hide parting lines on non-visible surfaces, ensuring a clean and polished finish.

3.Complex Geometries:

For parts with intricate shapes, curves, or angles, angled lifters provide additional flexibility to ensure complete molding and easy ejection.

4. Improved Production Efficiency:

Angled lifters simplify mold structures, reduce secondary operations (like manual trimming), and enhance overall production efficiency.

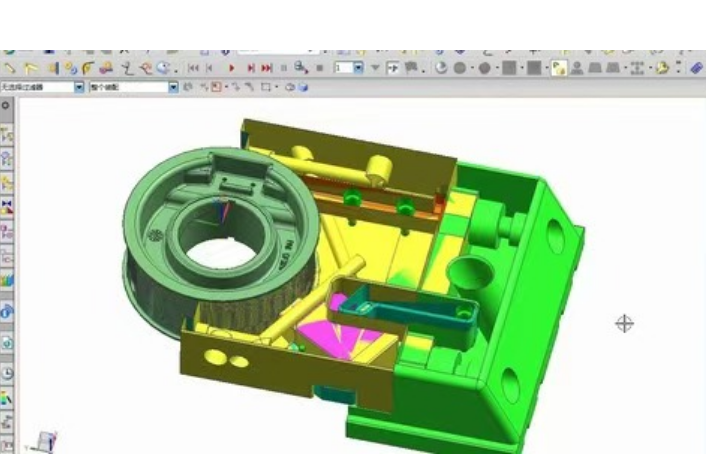

Key Design Considerations for Angled Lifters

Lifter Angle:

The angle of the lifter (typically between 10° and 25°) must be calculated based on the undercut depth and ejection force to ensure smooth operation.

Guiding Mechanisms:

Precision guiding systems (such as guide pins and bushings) are crucial to ensure smooth movement and prevent wear or jamming.

Material Selection:

Lifters and guiding components should be made from wear-resistant materials (e.g., hardened steel or carbide) to extend mold life.

Cooling System:

If cooling is required in the lifter area, proper cooling channels must be designed to avoid deformation or dimensional instability.

Ejection Force:

Ensure the driving force (e.g., springs, hydraulics, or mechanical systems) is sufficient to overcome ejection resistance without damaging the part.

Real-World Applications

Automotive Parts: Interior components, light housings, and handles often feature undercuts or complex surfaces.

Consumer Electronics: Phone cases, buttons, and connectors require high precision and smooth finishes.

Home Appliances: Washing machine panels, refrigerator handles, and other components with side features benefit from angled lifters.

Why Choose Sino-Mold?

At [Sino-Mold], we combine advanced engineering expertise with state-of-the-art manufacturing technology to deliver high-quality molds and machined parts. Whether you need a custom solution or expert advice on mold design, we’re here to help: louise@sino-mold.com/ sales@sino-mold.com Let’s turn your design challenges into manufacturing successes!